Valve Certification & Testing

NATA Accreditation & ISO 17025: 2017

VALVEX can test and certify any size, rating and type of valve to any specification and standard (Pneumatic or Hydrostatic).

Our procedures and QMS are ISO 17025 accredited to ensure the highest levels of safety and quality.

Some examples of testing and certification provided by EXGROUP include:

-

Shell and seat testing of valves including ball, gate, globe, butterfly, check and control valves.

-

Fugitive emissions testing.

-

Function testing, breakout testing and compatibility checks to ensure correct functionality of valves before they leave our door.

-

Calibration and testing of PSVs.

On-Site Support

Via Labour & Equipment Hire

VALVEX can supply valve specialists, engineers and qualified tradesmen, along with specialist equipment to any customer site throughout Australia, New Zealand, and internationally.

-

Process, Mechanical and Project Engineering Support, Mechanical Fitting, Electrical and Instrumentation Technicians, mobilised from ports all over Australia, New Zealand and Central America.

-

Offshore-rated 20-foot site mobile containers fitted out for repair, and pressure testing of all types of valves at our clients’ facilities.

-

Site-mobile PSV test bench and lapping equipment also included in either our offshore-rated 10-foot or 20-foot site-mobile containers.

-

Diagnostic testing equipment.

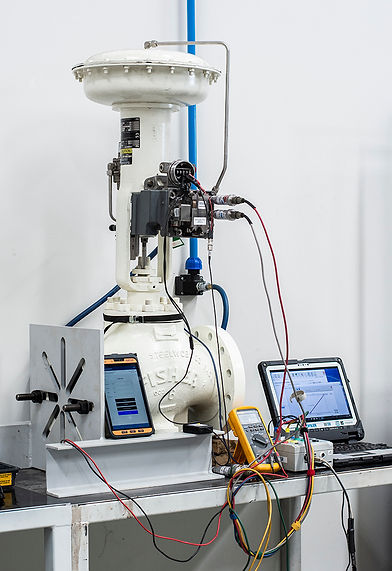

True Valve Diagnostics

Utilising state-of-the-art technology, VALVEX performs local diagnostics to evaluate control, solenoid-operated and critical valves on-site. We provide graphical data and analysis which allows our customers to plan outages and improve efficiency.

-

Non-intrusive predictive diagnostic testing on air-operated control, quarter-turn, choke and anti-surge valves.

-

General valve health check and signature testing.

-

Tune and calibration of positioners and solenoids on air-operated valves.

-

Digital speed response and step response testing.

-

Preventative and predictive maintenance controls.

Control Valve Calibration & Tuning

-

Calibration of 4-20 m/A, Pneumatic, Hart and Fieldbus positioners.

-

Positioner gain setting adjustment to optimise valve performance.

-

Tuning of anti-surge control valves to ensure they meets critical opening speeds

EXGROUP showed a level of professionalism that was very refreshing and appreciated.

The work scopes were followed safely and on time, and any concerns the team had were brought to our attention in a timely manner enabling the outage to remain on track

Maintenance Superintendent

Planning & Valve Management

VALVEX can plan client turnarounds/shutdowns and manage all client valves. We specialise in critical valve management, compliance audits, and campaign maintenance-style projects

-

Valve criticality review and sparing philosophy.

-

Warehouse management and maintenance of inventoried valves and spare parts

. -

Valve procurement, expediting, and third-party inspections (FAT).

-

Detailed planning of critical on-site valve repairs and/or replacements including improvements on design.

-

Condition monitoring.

-

EXTAG digitally documents compliance and quality data.

Overhaul & Testing Capabilities

For all types of valves

– mobile & in-house

VALVEX provides the very best servicing of every valve type. We can provide services on-site and in-house, refurbishing valves and restoring them to OEM specification.

From safety valves to control valves, we ensure your valves are overhauled and serviced by our experienced technicians.

Valve Engineering &

Third Party Failure Analysis

At VALVEX we utilise our expertise and experience to deliver independent valve, control and process engineering.

We focus on international design practices and in-house knowledge to ensure client compliance, and our independent analysis drives value addition as an end result.

Integrated Management Systems with accreditation to ISO 17025, 9001, 45001 and 14001

Valve Procurement

& Bid Analysis

VALVEX can draw upon its independence and many years of experience to ensure all valve procurement bids are technically compliant and cost effective.

We achieve this by drawing on multiple suppliers and completing all administrative work to present the best value-added option to our customers.

Safety Devices, PSV Testing, Overhauls & Certifications

VALVEX has a QMS that is accredited to ISO 17025. Couple this with our experience and expertise, and we ensure the best safety device certifications, overhauls and repairs available.

We can also complete in-situ PSV testing of boiler safety devices for our customers.

Critical Equipment Information Tool

EXTAG provides instant access to critical equipment information including Data Sheets, Test Certificates, ITP’s and operations and maintenance data. Customers use EXTAG with its intuitive learning interfaces to collect and visualize field data through construction, commissioning and operations phases